Hot runners and silicone ranges offer

Hot runners and silicone ranges offer

Our hot runner and silicone ranges offer injection with open nozzles and shut-off nozzles. Using standard components, our dedicated team covers every phase from design to prototyping and series production development.

Using a range of different nozzles adapted to suit the specifications of the component to be molded (volume, material, dimensions, etc.), we produce every part of the injection assemblies ordered by our customers.

Hot runners

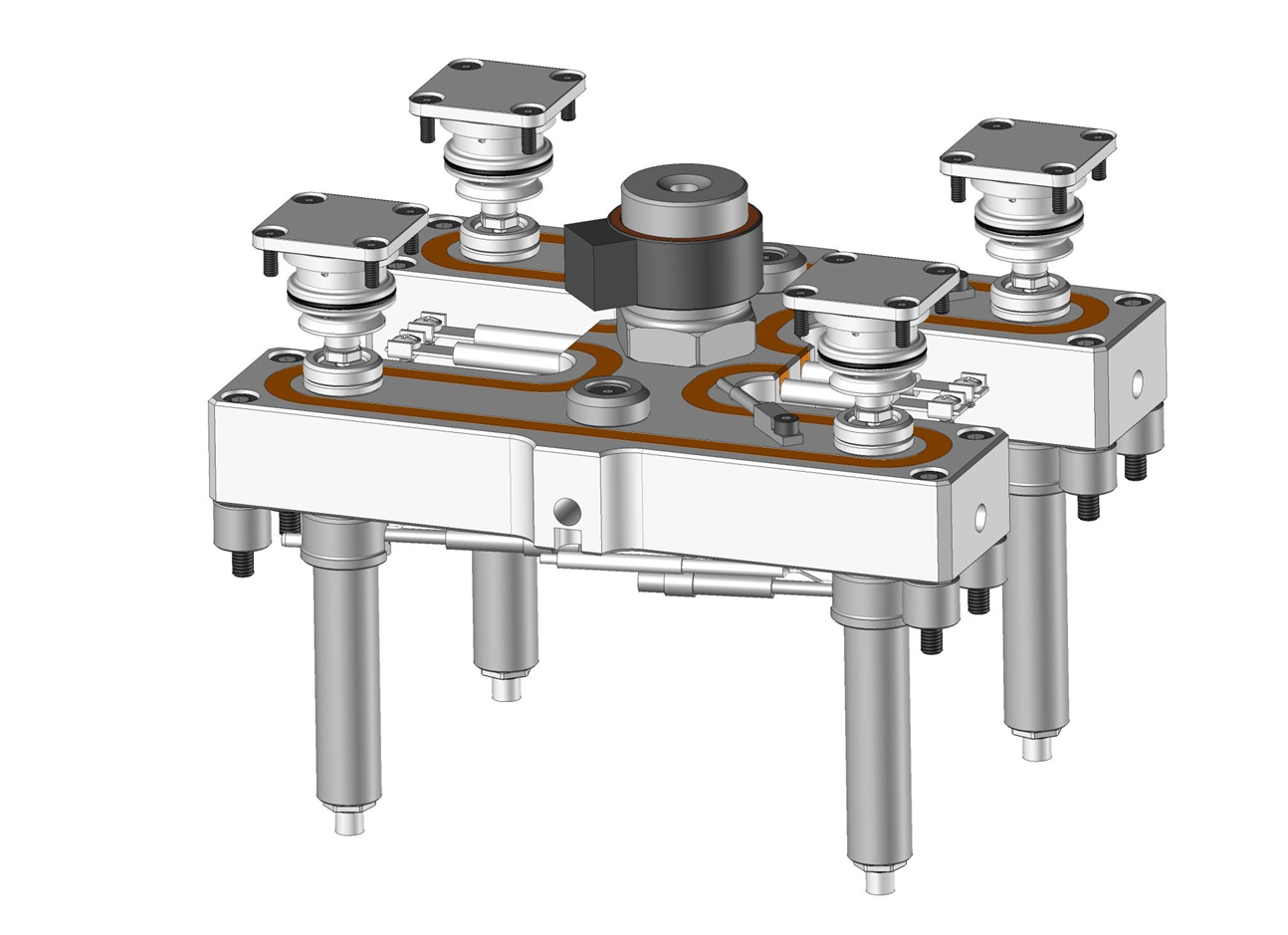

The RABOURDIN range of hot runners features its own designs based on small multipoint nozzles developed from the modules of the Rabourdin RP range. These components are used in complete systems designed specifically for midsize or large production runs of small injection components.

Why choosing us ?

These cylindrical nozzles are available in diameters from 20 to 80 mm, with between 2 and 8 points designed to provide a balanced input flow for cavities between 0.1 and 10 cm³. Used in conjunction with a manifold, they provide the option to assemble hot channel systems for 64 mold cavities… or more.

These nozzles simplify installation in multi-cavity molds because there is only one heating zone per nozzle; a design feature that delivers significant energy savings.

RABOURDIN offers you a comprehensive range of mold equipment.

In addition to expert technical support, our customers also receive qualified and highly responsive Post Sales Service.

Cold runners

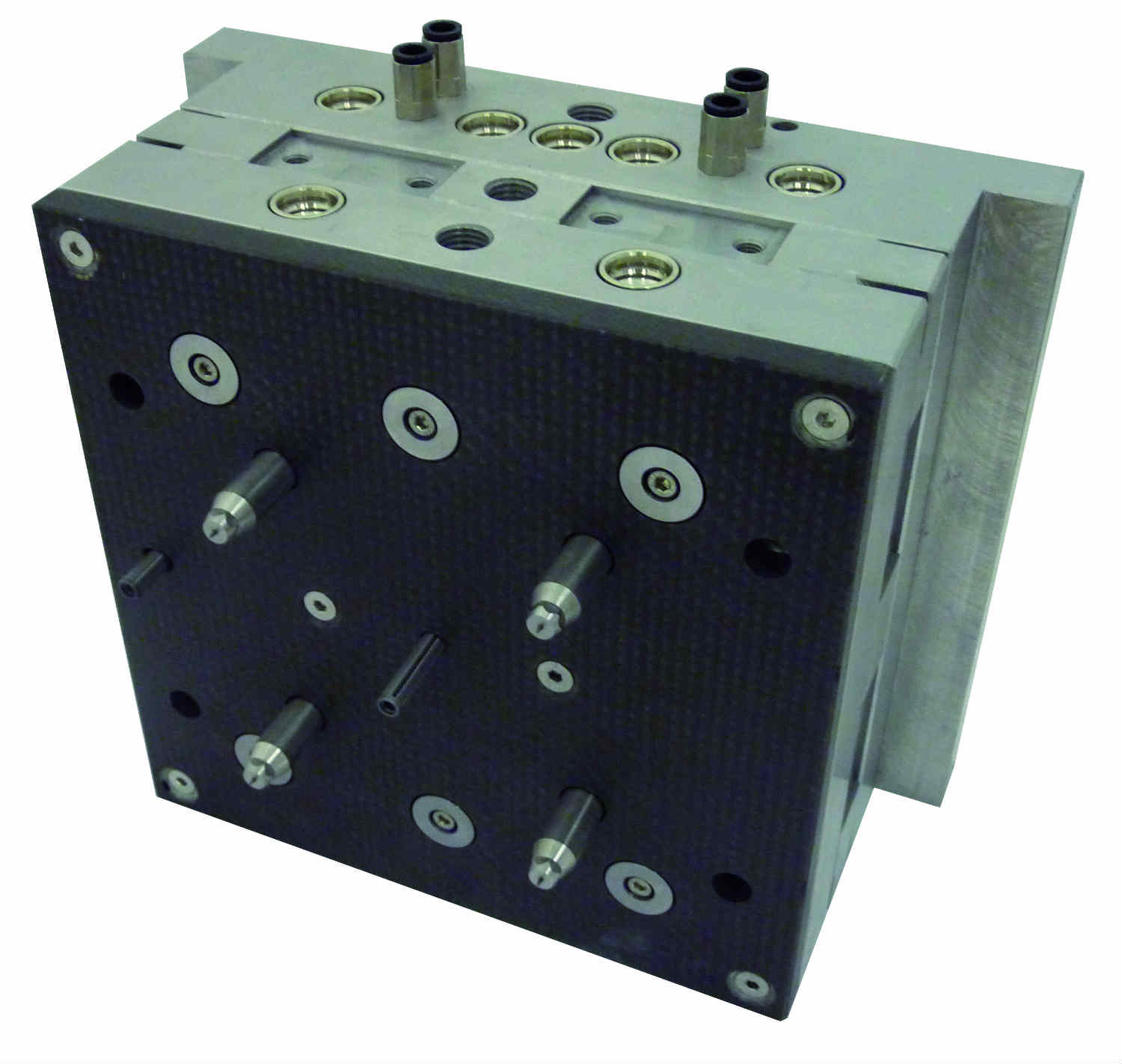

RABOURDIN innovation has driven advanced developments in the injection of LSR- type liquid silicons and rubbers.

RABOURDIN standardized solutions are technically proven to deliver significant gains in terms of productivity and maintenance. RABOURDIN cold runner blocks help our customers to design reliable multi-cavity tool solutions.

In addition to expert technical support, our customers also receive qualified and highly responsive Post Sales Service.

Work carried out alongside mold makers and converters to develop and perfect silicon molds has allowed us to develop the expertise needed to offer a one-stop solution from component design to mold construction.

Why choosing us ?

These complementary technologies enable RABOURDIN to respond effectively to the need for complete injection solutions for even the most complex multimaterial, silicon and thermoplastic molding needs.